(BAR-44) Gee Bee Pod Racer

I saw the rendering below on the Facebook Dieselpunk Gallery.

It's kind of a bash of Star Wars pod racers, and what I believe to be a 1930's Gee Bee Model R Super Sportster air racer. Gee Bee's were purpose built, just for racing. A way cool airplane that doesn't look like it should even fly.. but fly they did. In 1932 it not only won the Thompson Trophy Race, but actually lapped all the other competitors, except one.

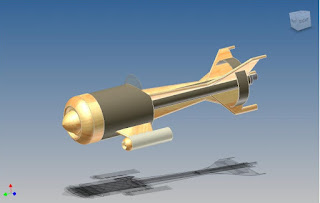

Here's the final design I'll enter into CAD.

It's kind of a bash of Star Wars pod racers, and what I believe to be a 1930's Gee Bee Model R Super Sportster air racer. Gee Bee's were purpose built, just for racing. A way cool airplane that doesn't look like it should even fly.. but fly they did. In 1932 it not only won the Thompson Trophy Race, but actually lapped all the other competitors, except one.

Here's the final design I'll enter into CAD.

- Standard Front Eject

- Flies on a single 29mm Motor

- Using a piece of 3" Steel Pipe as Ballast, buried inside the nose.

- 30" Dia Nylon Chute

- Onboard Altimeter Stowage

- 4" Dia. Nom. Body

2025-03-21

I was able to finish the CAD Model and create an outline drawing of the BT-400 version. Pretty pleased with the results.

2025-03-21 Drawing Set, Sheets 1 through 10, Rev 00

Somewhere in this mass of wood hides the Engine Cowling / Nose Cone of a Gee Bee Pod Racer.

A 6" piece of 4x4 and (4) 1x4's.... all glued together to be turned on my wood lathe.

A 6" piece of 4x4 and (4) 1x4's.... all glued together to be turned on my wood lathe.

2025-03-24 Prepped the wooden block for turning using my table saw.

2025-03-28 Centering Rings and Body Tubes

I made the Centering Rings from 1/4"

plywood using a Fly Cutter, a Forstner Bit and my Wood Lathe. Then

started wood gluing the Front Centering Ring to the Nose Cone, and the

BT/C-80H to the Nose Cone / Front Centering Ring.

Also located my stash of now vintage B-B's, which I'll be using for Ballast instead of the 3" Sch 40 Pipe.

2025-03-29 Nose Cone Ballast

I used 16 Ounces of "Copper Head" (good name for a rocket)

B-B's. Placed a 3rd of them, drizzled some wood glue on them, and

repeated that 2 more times. I then placed a centering ring over the

B-B's and glued it into place.

Weight of the copper plated steel B-B's is approximately 2.24 Ounces per Cu-In.

Rear Fins CWF, Slotting the C-55 and beginning to installing Fins

2025-04-01 Intermediate Fin Initial Gluing and Slotting the BT-400

2024-04-02 Gluing the TTW Pod Fins to the BT-400

I dry fitted the internal Centering Ring

to the BT-80H and it's a tight fit. So I decided to leave it there

temporarily and glue the Pod Fins to the BT-400. That should help to

keep the BT-400 in place once the glue dries. I can then glue the pods

to the BT-80H.

The

rectangular box in the 3rd photo was made from some scrap BT/C-60 from

the fin tubes on my Fleet Interceptor. It will glue inside the BT-400

and act as a stowage compartment for my Altimeter Two.

Gluing the TTW Pod Fins to the BT-80H

Laying down a couple wood glue fillets, then placing the Centering Ring back on.

2025-04-03 Gluing Internals

Finished up gluing the internals of the TTW Fins and then glued the Altimeter Stowage box inside the BT-400. That's it for the internals, so the Rear Centering Ring had wood glue inserted into the tenon for the BT/C-80H and also on the TTW fin ends. The Centering Ring was then put into place and the assembly was set upright for drying.

2025-04-04

Gluing the : Centering Ring to BT-400, Dash to Centering Ring, and Rear Fuselage to Centering Ring

- Used Gorilla Wood Glue to attach the Centering Ring O.D. to the BT-400.

- The Dash was cut from 1/8" Basswood, Sanded the Centering Ring boss to match the angle of the BT-400 and then glued the dash in place.

- A generous amount of wood glue was applied to the Centering Ring center hole, as well as to the Rear Fuselage Center Tube and the ends of the Intermediate Fins. The Rear Fuselage was then set into place on the Centering Ring and shimmed for plumb.

Photo Shoot

2025-04-05 Installing the Side Pod Body Tubes.

These were originally designed to be

motor tubes, so they needed to be able to handle the thrust. That's the

reason for the TTW Fins and the Body Tube slicing and dicing.

Since

they also need to support the weight of the finished rocket, which at

over 2-1/4 lbs is pretty substantial. I figured I'd go ahead and leave

the design Hell-For-Stout.

I used @AeroTech 's fin mounting arrangement... but in reverse.

2025-04-06

No comments:

Post a Comment