04-04-2024

Applied some Rustoleum Clear and the Sharpie colors didn't run... yipee.

04-03-2024 Radiator

04-02-2024 Distressed Paint

I sanded the white paint to give the rocket a worn and torn look. I then used a Sharpie to add the blue, sanded the blue, and then used Acetone to smooth out the blue. Also used a black Sharpie on the windows and air inlets.

03-31-2024 White Paint

03-30-2024 Primer Day 02

03-24-2024 Primer Day 01

The weather is once again wreaking havoc here.

I wanted to get the 1st coat of primer on the rocket to see how the panelizing looks. Thermometer read 44 F. I ran some hot water into a mug and tossed the can of primer into it, and headed out back to set-up the Workmate. Hurried back inside, grabbed the rocket, the primer, the camera and a paint mask and headed out. Just as I finished the first coat and was take some photo's the flurries started. So I picked up the Workmate & rocket and carried the to the covered breezeway.No drips, no runs, no errors.

The temp's are now dropping like a rock.... 38 F.

Fast forward 20 hours

03-23-2024 Panelizing, Day 03 and, err, Launch Lugs

I was installing the last few panels today and thought "Launch Lug, hey, where's the launch lug?"

Well, I installed a couple 3/8" lugs on the lower body , on either side of the nose to clear the chin spoiler.

03-17-2024 Panelizing, Day 02

Added windows to the cockpit and some structural "stuff" down the backbone.

03-16-2024 Panelizing, Day 01

02-03-2024

Air Inlet Redux

Yeah... didn't like those wimpy air inlets... so I replaced them with a glued up composite of (5) pieces of 1/16" thick balsa. Then sanded them into submission.

02-02-2024

It's been cold, which limits barn time, so slow progress. It's good weather though to update the CAD files. See the 01-16-2024 journal entry below.

Made a couple of snorkel style air inlets, and the fairings for the lower stabilizers. Used home made balsa plywood since these parts are non-structural and not in harms way. I'll use some CA to harden these pieces.

01-28-2024

Swing Test Video and Progress Shots

Swing Test - USS Edsel Ford - A Sci-Fi Flying Model Rocket (youtube.com)

Gluing the top and side plates.

01-27-2024

Gluing the nose cone to the BT/C-300. My "Circle of Friends" help hold the rocket in position.

Titebond Quick and Thick fillets on the nose cone.

01-26-2024

Upper Radiators

And Glue Fillets

01-25-2024

Started installation of the lower radiators. These are tricky: I drew lines on the nose cone spaced 22-1/2 degrees, then used some masking tape.

01-24-2024

Sanded the cockpit outside and then started gluing it and the chin spoiler to the nose cone.

01-23-2024

Cut the nose cone accessory parts from 1/4" plywood. Also rough cut the cockpit from (2) pieces and glued them together and will finish cut them after the glued has dried.

01-21-2024

Gluing 1/16" Basswood to the fincan sides, and installed the 1/4" dowels for the fuselage 1/16" Basswood.

01-20-2024

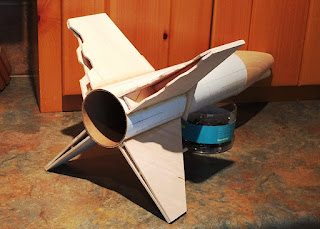

Mockup

Nose Cone Turning / Fabrication

01-19-2024

Stabilizer, continued

The alignment fixture worked like a charm.

Stabilizer Build Day 2

Sanded the stabilizers and added glue fillets before attaching them to the BT/C-300 tubing. Also took the time to make a cardboard fin alignment fixture.

01-18-2024

Stabilizer Build Day 1

These are made from 1/8" Basswood, and 3/16" poplar dowels.

01-16-2024

I made an update to the CAD Model and flipped the upper vertical stabilizers. This makes the model look much more like the sketch by Galan Pang.

01-09-2024

Here's a truly awesome design by Galan Pang.

I created an OpenRocket design, starting with a BT-300 tube. This will use a 29mm composite motor and be a rear eject design.

Next up is to create a CAD Model and Dwg Set.