(BAR-46) The Lucky 7

I got this design from a fellow rocketeer over at TRF, whose member name is Babar. Here's a link to his original design... 2FNC--- 2 linear fins and a nose cone. The Lucky 7

I thought I'd take a crack at making one of these that'll fly on 24mm

motors. It's got a place for my Altimeter Two and will handle any

Estes or Aerotech 24mm motors. Some dowels were added on both sides of

the fin, and it also has doubled up body tubes, just to ensure

longevity. I'll use some 2 ply's of 1/16" thick Basswood to make those

1/8" Basswood fins.

The plan is to start with the D12-7 BP motor... and work my way up to the Aerotech F32T-8.

The plan is to start with the D12-7 BP motor... and work my way up to the Aerotech F32T-8.

Got to spend a little quality time out in the barn this afternoon. Turned the Nose Cone and Transition on my wood lathe.

2025-04-25

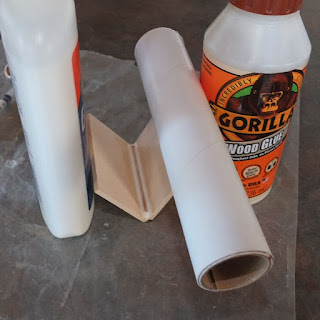

Body Tubes, Mock-Up, Lag Screw Eye, and Gluing Begins

2025-04-25

2025-04-29

Revised the Ejection Tube... actual parts and new drawing set. Gluing on the Upper Launch Lug.

2025-05-01 Swing Test

Just when you've got this whole rocketry thing figured out... you realize you don't. I swing tested the rocket today and it was not stable. No matter the orientation, it just wouldn't fly nose first reliably.

So the nose cone was bored for a 3/8" dia piece of ballast x 1.1" long, 15 grams.

That did the trick. Sim shows the rocket is now at 1.6 caliber or 10.6%. I think it was the % that bit this rocket, which I usually shoot for 8% to 12%... which it was under this time without ballast.

I tested the rocket in (3) orientations, all were stable, (1) is posted up here.

Just when you've got this whole rocketry thing figured out... you realize you don't. I swing tested the rocket today and it was not stable. No matter the orientation, it just wouldn't fly nose first reliably.

So the nose cone was bored for a 3/8" dia piece of ballast x 1.1" long, 15 grams.

That did the trick. Sim shows the rocket is now at 1.6 caliber or 10.6%. I think it was the % that bit this rocket, which I usually shoot for 8% to 12%... which it was under this time without ballast.

I tested the rocket in (3) orientations, all were stable, (1) is posted up here.

2025-05-03

Finished the rocket by applying some CWF to the Nose Cone and the

Transition, followed by sanding on my wood lathe. It's ready for paint.